Products

Classification by industry

Classification by mechanical model

No data

MUCH PRODUCTS

Products

Bar tube dry bag isostatic press

The dry bag isostatic press adopts prestressed steel wire winding working cylinder, prestressed steel wire winding frame, mobile lower bearing platform, lower discharging, hydraulic pre-pressurization, supercharger pressurization system and rubber liner isolation. Mainly used for alumina, zirconia, silicon nitride, hard alloy, magnetic materials or other similar materials, thin rods or tubes of isostatic pressing.

Learn MoreThe vertical cold isostatic press adopts the prestressed steel wire winding structure, which has high fatigue strength, reasonable force, safety and reliability, compact structure and light weight. It is mainly used for the forming of semi-finished parts of powder products before sintering and the preforming of hot isostatic pressing blank. The pressed products have high density, uniform density distribution and good isotropic properties. They are widely used in powder products of various cemented carbide, refractory materials, magnetic materials, ceramics, graphite, non-ferrous metals and high specific gravity alloys.

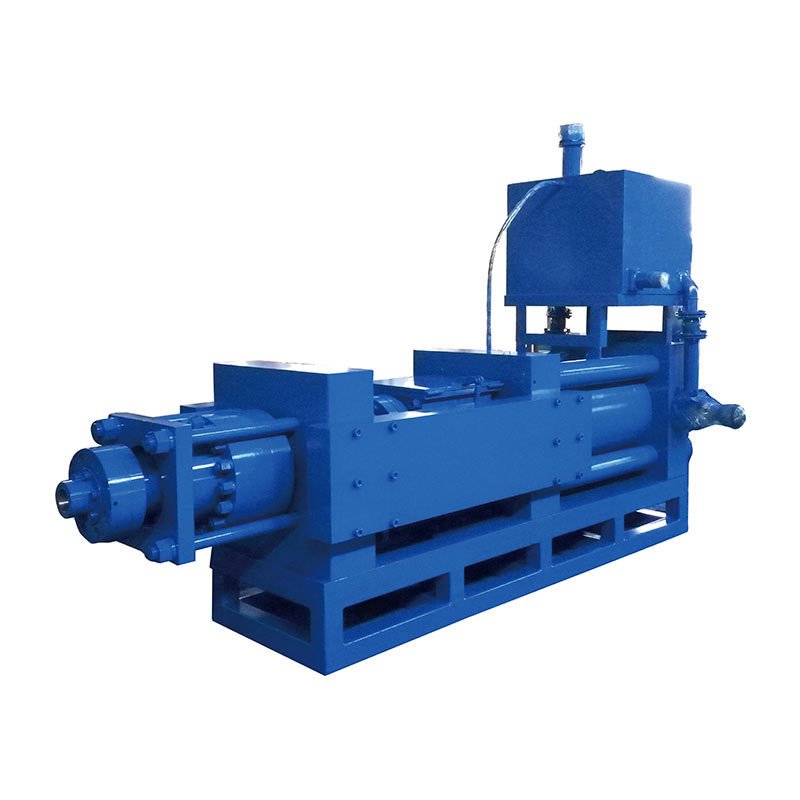

Learn Morehydraulic extrusion forming machine

1. Features and Uses The Maxtor hydraulic extrusion forming machine is designed as a horizontal notch feeding machine with a vacuum box to vacuum the mud. Magchi hydraulic extrusion forming machine is especially suitable for the extrusion forming of special ceramic tubular bodies such as alumina and silicon carbide, and the moisture content of mud material can be as low as 13% ~ 15%. Can also be used for other similar ceramic products, such as extrusion molding work. II. Technical Parameters and Serial Number of Magchi Hydraulic Extrusion Forming Machine Performance Index Unit JC150AJC200AJC300AJC400A1 Nominal Axial Force of Extrusion Cylinder kN15002000300040002 Rated Working Pressure of Extrusion Cylinder MPa 20202018.53 Maximum Stroke of Extrusion Cylinder mm1000100010008004 Diameter (Inner Diameter) mm2002202703005 Extrusion Head Fast Forward Maximum Speed mm/s1001001001006 Extrusion Head Slow Forward Maximum Speed mm/s141212107 Extrusion Head Return Maximum Speed mm/s1501501501508 Motor Power kW222230379 Overall Weight t67911

Learn MoreTwo-way floating mold frame hydraulic press

1. Features of Two-way Floating Mold Frame Hydraulic Press The two-way floating mold frame hydraulic press is actually an upper two lower one hydraulic press. The upper main oil cylinder and the lower main oil cylinder are equal in size, which can realize multiple exhaust, two-way pressurization, mold frame floating protection demoulding, and the pressing action can realize full automation.

Learn MoreOne-way floating mold hydraulic press

1. Features of one-way floating mold frame hydraulic press The one-way floating mold frame hydraulic press is a two-action hydraulic press in the real position. When pressing, the mold frame can float, exhaust multiple times, pressurize one-way, and the pressing action can realize full automation. 2, one-way floating mold frame hydraulic press use one-way floating mold frame hydraulic press is especially suitable for alumina, zirconia and other small thickness size, density uniformity requirements are not high products such as wear-resistant lining, lining rapid dry pressing forming, can also be used for similar powder products blank dry pressing forming.

Learn More